Masterpieces in oils

The best ones offer a hint of artichoke, dry grass, berries, citrus fruits or pepper. We are talking about olive oil here. Continue reading

Olive oil – a masterpiece of nature that is never missing from Mediterranean cuisine.

Just drizzle some good olive oil onto a hunk of bread, and you have a delicacy to delight both your palate and sense of smell. The bad news: top-quality olive oils are expensive. If the testers at Stiftung Warentest (a German consumer organisation) are to be believed, you will have to fork out at least €24 for a litre of olive oil classed as “very good”. Something as exacting as this requires a lot of preparation and attention to detail.

So how is olive oil produced?

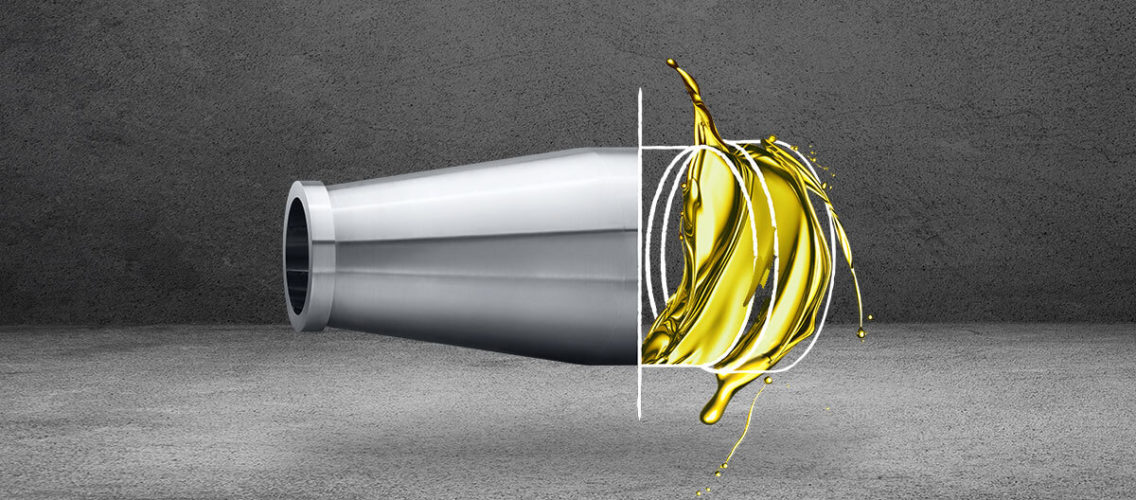

The most important ingredient is olives, of course. They should not be too ripe. Immediately after the harvest, and ideally on the same day, the olives and their stones are cold-pressed and kneaded into a pulp. Further pressing and centrifuging then separate the olive oil from unwanted items like skin, stones and pulp residue. This is where components supplied by Kuhn Special Steel come into play.

Stainless steel delivers top quality

In the first stage of the process, a decanter centrifuge removes solids from the olive-oil suspension. Separators are then used to clarify the resulting liquid and remove superfine solids from the oil, as part of the final clarification and refining process. It is important that all the natural components of the oil, such as polyphenols, are preserved, as these are what give olive oil its intense flavour. Components supplied by us are used in both the decanter centrifuges and separators. The conical and cylindrical drums, for example, and worm-feed assemblies of the decanter centrifuges and the distributor bases in the separators are all made of our stainless steel. We work here to tolerances of thousandths of a millimetre. Finally, the purity of the olive oil is reflected in its flavour. The components concerned must also conform to maximum standards of hygiene and likewise be highly resistant to wear and corrosion. This keeps the equipment concerned “low-maintenance”, while helping to ensure that the top-quality end product is not even more expensive.

It only remains to wish you bon appetit!

Photo: © chandlervid85 – stock.adobe.com, Kuhn Edelstahl