Water! Water! – Kuhn Special Steel delivers

According to UNICEF, 2.1 billion people (i.e. approximately 27% of the world’s population) have no access to clean water. This is a frightening statistic. Continue reading

Some 884 million people likewise have no safe access to the water that is available. The word “safe” is used to describe a water supply that is close to a person’s home, available when needed and free of contaminants. Water meanwhile accounts for more than two-thirds of the Earth’s surface, although only 0.3% of it is actually drinkable. Kuhn Special Steel is helping to increase this percentage – in various different ways.

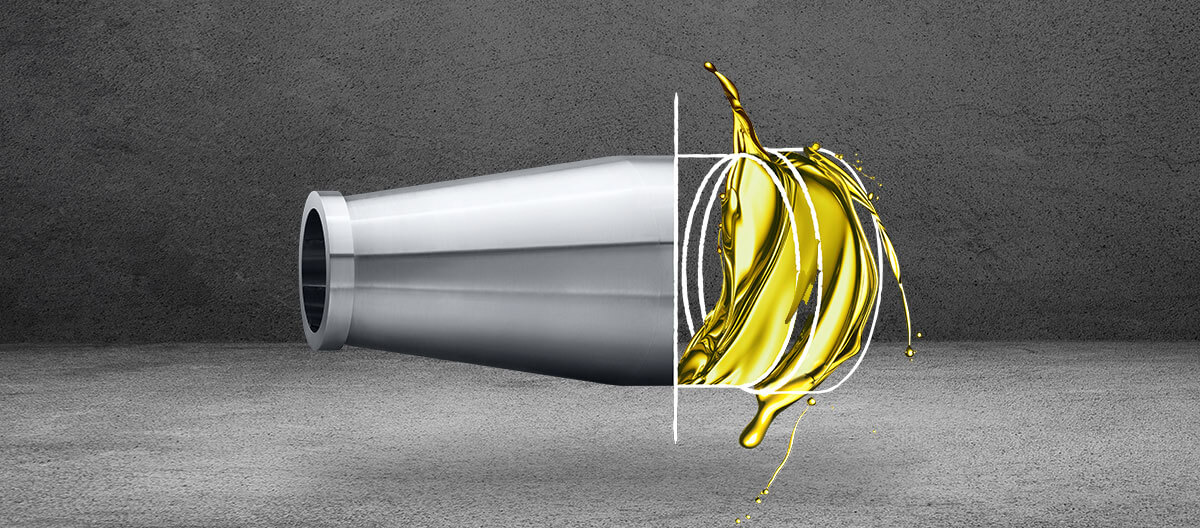

Cleaning of recycled water

We have been supplying worm-feed assemblies and components along with drum casings for solid bowl centrifuges for several years, for use in the treatment of waste water and paint sludge. The operating principle of a solid bowl centrifuge has hardly changed since the nineteenth century: the contaminated water destined for treatment enters the screw mechanism via an inlet, after which it is purified by centrifugal action. The decanter expels the resulting solids via a series of discharge outlets. The decanter drum is then brought up to its maximum turning speed, and the foreign bodies in the water are deposited on the inner wall of the drum. The screw mechanism acts as a conveyor, removing the deposited solids from the end of the drum and thus separating them from the water. The materials used need to be resilient to great strain, as they are subject to the action of anything from water and acids to plastics and metals, along with other items; all of which expose them to constant mechanical and chemical wear.

Acid-resistant stainless steels

Kuhn Special Steel is therefore developing components made of rustproof and acid-resistant stainless steels designed to meet these particular needs. They resist corrosion and are characterised by high levels of durability, which slows down wear. The decanter seldom requires an overhaul, which allows the plant system to run longer in fault-free operation. In other words: more waste water can be turned into drinking water.

Making seawater drinkable

We are also active in the production of components designed for systems that desalinate seawater, which accounts for about 97% of the world’s available supply, to make it suitable for drinking. Modern desalination plants use electric pumps to force seawater through a series of chambers containing semi-permeable membranes with a “salty” and “fresh” side. This is likewise an area where our components need to be highly resistant to wear and corrosion.

The world’s population is growing every day – and with it the demand for clean water. Kuhn Special Steel is helping to ensure that people are supplied accordingly.

Photos: lessingtiede; © pichitstocker – stock.adobe.com