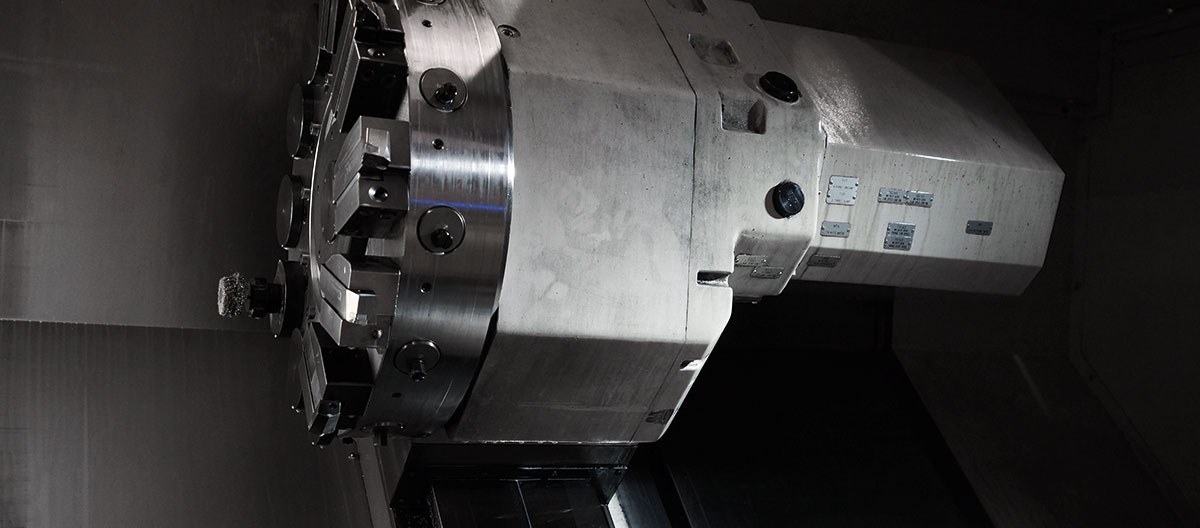

Our range of plant machinery continues to grow: OKUMA arrives

Anyone who knows anything about CNC turning machines will be familiar with OKUMA. Continue reading

OKUMA, a Japanese company famed for supplying unmatched long-term precision for well over a hundred years.

An OKUMA LU 45M machine has formed part of our plant facilities since a few weeks ago. This heavyweight piece of kit is ideally suited to the four-axis synchronous and simultaneous machining of large workpieces.

“We had been looking for a machine capable of carrying out heavy cutting jobs, and the OKUMA unit is well up to the task. It works to tolerances of as little as 0.01°, and is also highly robust and reliable”, in the words of Sinisa Simovski, the head of Kuhn Special Steel’s Mechanical Production Department.

It reduces downtime and prevents bottlenecks, and can also handle workpieces with a large length-to-diameter ratio – a key performance factor for virtually all components made of horizontal centrifugal castings – thanks to its solid construction, generously sized, ground flat-bed configuration and its ability to operate perfectly in three high-torque dimensions. It should therefore come as no surprise to find that we are also using this OKUMA machine in the area of decanter and valve technology.

Maximum flexibility

Another advantage offered by this machine is that there are no restrictions regarding materials. “We are very flexible in this respect. And we need this flexibility because, as many will know, we work for a range of different industries. As specialists in individual customisation, we also have to adapt ourselves continuously to our customers’ circumstances”, he adds.

This CNC unit is also flexible when it comes to controlling it, with an OKUMA configuration designed to run completely independently of other operating systems. This saves a lot of time for the people who program it, while ensuring an ease of operation that sets benchmarks for today’s industry. In short: The OKUMA LU 45M meets top standards in performance-oriented turning, drilling and milling tasks.

“Our plant machinery is already at the forefront of the world’s centrifugal casting sector, and our latest investment is helping us to build on this for the benefit of our customers, who expect us to supply individual solutions of the highest quality. This is what the LU 45M is allowing us to do”, says Andre Kuhn, CEO of Kuhn Special Steel.

Photos: Dirk Breuer; Kuhn Edelstahl