Behind the scenes

Pieces of heavy equipment, great heat and molten metal are the ideas and images that many people associate with work in a steel foundry, but they actually show only part of what goes on at Kuhn Special Steel. Continue reading

Many tasks do not fall under the classical notion of what the tasks of a foundry worker entail, despite being essential to the smooth running of all the processes involved.

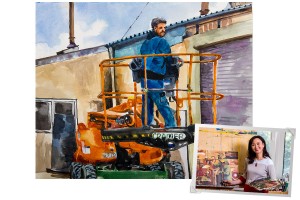

Frank Schäfer has captured just such a task with his Canon EOS 700D. Employed in the company’s software development department since 2003, he likes to use his camera in his spare time to take on-the-fly photos of the site in action. This is how he came to take the picture entitled Moving up, which shows a colleague from the maintenance team as he repairs a roller shutter. The scene captured is highly symbolic of the many busy hands that make the work of the foundry possible – even if they are employed quietly and in the background.

Frank Schäfer has captured just such a task with his Canon EOS 700D. Employed in the company’s software development department since 2003, he likes to use his camera in his spare time to take on-the-fly photos of the site in action. This is how he came to take the picture entitled Moving up, which shows a colleague from the maintenance team as he repairs a roller shutter. The scene captured is highly symbolic of the many busy hands that make the work of the foundry possible – even if they are employed quietly and in the background.

The maintenance team remains on call right around the clock, throughout the 52,360 square metres that the site occupies. Its members are responsible for the care, maintenance and – when required – repair of, among other things, nineteen centrifugal casting machines, fifteen induction and heat-treatment furnaces and no fewer than eighty lathes and machining centres. The maintenance department also deals with the setup of new items of machinery. This demands specialist expertise from all concerned, as the machines used at Kuhn Special Steel are normally made for special purposes. They are designed and developed by the company in-house to supply further innovative enhancements to existing procedures and processes in the area of centrifugal casting.

The department likewise implements modernisation measures in general. Examples of this include the current adaptation of the plant’s lighting systems to work with energy-efficient, environment-friendly LED technology. This task requires strategic planning and a delicate feel in order to ensure that day-to-day operations and workflows are not disrupted.

The Kuhn calendar initiative, a creative project carried out jointly with the painter Cindy Kuhn-Chuang and employees of Kuhn Special Steel, aims to capture photographic impressions of our working environment.

The Kuhn calendar initiative, a creative project carried out jointly with the painter Cindy Kuhn-Chuang and employees of Kuhn Special Steel, aims to capture photographic impressions of our working environment.

A snapshot of the photographer

Name:

Frank Schäfer

Since when have you been working for the company?

since 2003

What do you do there?

software development

How and when did you take up photography as a hobby?

My wife was given an SLR camera as a present, but it was me who was delighted!

Welches Kameramodell nutzen Sie?

A Canon EOS 700D.

What are your favourite subjects?

People

Photos: lessingtiede