Moving in unison

Even in one of the largest and most modern production plants in the centrifugal casting sector, technology is not the only thing that counts. Continue reading

What goes on in our plant – both on the machines and behind the scenes – depends largely on the smoothly running joint efforts of our workforce.

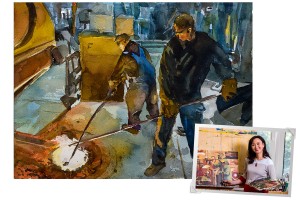

Our former employee Dirk Breuer illustrates this cooperation particularly well in his photograph entitled Teamwork. It portrays two foundry colleagues, standing by one of the company’s seven medium-frequency induction furnaces. These floor-embedded furnaces operate at an average temperature of around 1,680°C. Your physical movements need to be fast and sure-footed when working with this kind of heat. While one employee skims of the resulting slag, the other takes a material sample. This highly trained two-man team masters the corresponding tasks smoothly and with few words, despite the exhausting physical effort involved. Dirk Breuer, who was himself employed at Kuhn Special Steel for fifteen years as a shipping manager, product-improvement executive and staff trainer, appreciates the importance of focusing on this aspect of the job: “When things get difficult, a helping hand is absolutely vital. Teamwork functions particularly well in the foundry, even when few words are exchanged.”

Our former employee Dirk Breuer illustrates this cooperation particularly well in his photograph entitled Teamwork. It portrays two foundry colleagues, standing by one of the company’s seven medium-frequency induction furnaces. These floor-embedded furnaces operate at an average temperature of around 1,680°C. Your physical movements need to be fast and sure-footed when working with this kind of heat. While one employee skims of the resulting slag, the other takes a material sample. This highly trained two-man team masters the corresponding tasks smoothly and with few words, despite the exhausting physical effort involved. Dirk Breuer, who was himself employed at Kuhn Special Steel for fifteen years as a shipping manager, product-improvement executive and staff trainer, appreciates the importance of focusing on this aspect of the job: “When things get difficult, a helping hand is absolutely vital. Teamwork functions particularly well in the foundry, even when few words are exchanged.”

Smelting is not just an essential stage in the production process; it is also a key factor determining material quality. Temperatures are checked and material samples are taken at regular intervals throughout the smelting process. This prevents overheating of the furnace, and ensures that an optimum temperature is maintained for the material concerned. Evaluation of the samples taken allows the process to be tweaked accordingly. Once all the readings are correct and the desired temperature has been reached, the molten steel can be poured into the foundry ladles for transporting to the centrifugal casting machine that completes the process.

The material specifications are supplied, and regularly checked, by our Quality Assurance (QA) Department. The corresponding team of PhD-level material scientists is also our customers’ key contact when it comes to research, optimisation and developments involving the materials that we supply. We confidently handle more than four hundred different alloys for use in a wide range of industrial sectors and markets. Our QA Department also has access to an in-house materials laboratory with a large selection of the latest test equipment in order to ensure the quality of our components and the processes used to create them. Kuhn Special Steel can therefore carry out virtually all destructive and non-destructive testing right here on the premises, in fulfilment both of customers’ requirements and those of the different approval bodies involved.

The Kuhn calendar initiative, a creative project carried out jointly with the painter Cindy Kuhn-Chuang and employees of Kuhn Special Steel, aims to capture photographic impressions of our working environment.

The Kuhn calendar initiative, a creative project carried out jointly with the painter Cindy Kuhn-Chuang and employees of Kuhn Special Steel, aims to capture photographic impressions of our working environment.

A snapshot of the photographer

Name:

Dirk Breuer

How long did you work for the company?

15 years

What do you do there?

Shipping management, quality assurance management and staff training.

How and when did you take up photography as a hobby?

I first started annoying my family with an SLR camera in 1978. Then I embarked on a long break. The new technology bug bit me about eight years ago, and I took up photography again.

What kind of camera do you use?

Sony Alpha 77 APSC and Sony Alpha 99 VF.

What are your favourite subjects?

People, time exposures and nature.

Photos: lessingtiede